The Challenge Unfolded:

A global leader in industrial manufacturing aimed not only to transform its approach to equipment management beyond traditional GPS tracking but also to unlock new revenue opportunities. Partnering with HoloTrak, they explored the potential of their equipment’s data generation capabilities. This collaboration aimed to elevate operational insights and equipment health monitoring, promising significant advancements. It also paved the way for a new, subscription-based revenue model, offering customers valuable analytics on equipment health, thereby opening new avenues for business growth.

Solution:

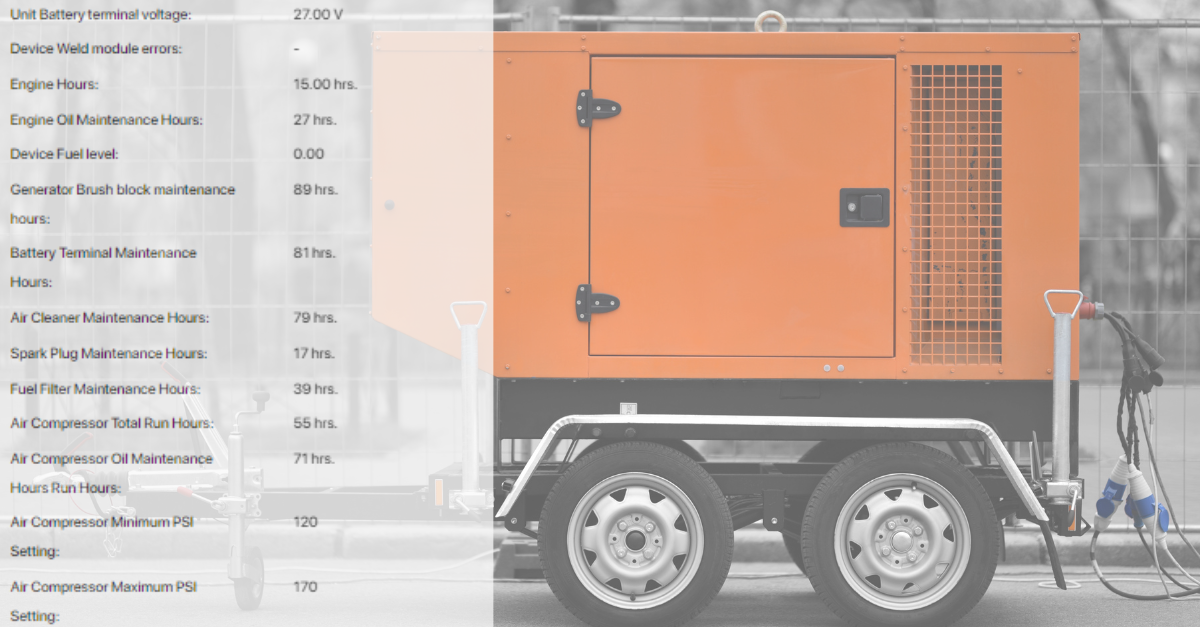

HoloTrak stepped in to bridge this gap by introducing the power of CAN Bus telematics data extraction. This innovative approach leveraged the existing technological infrastructure their machines powered by Kohler and Kubota engines, known for their durability and performance. By tapping into the CAN Bus system of these machines, HoloTrak was able to extract over 50 Parameter Group Numbers (PGNs), enriching the manufacturer’s data analytics capabilities far beyond initial expectations.

The integration of these PGNs into HoloTrak’s platform enabled comprehensive monitoring of various metrics such as engine oil maintenance hours, fuel levels, compressor run times, hydraulic system metrics, and specific application software information. This wealth of data provided nuanced insights into the health and performance of the equipment, surpassing the traditional functionalities offered by GPS tracking.

Outcome:

The implementation of this advanced telematics system led to the establishment of a new revenue stream for the manufacturer, based on a subscription model leveraging comprehensive data analytics. This model provides customers with in-depth insights into the health and operational efficiency of their equipment. By accessing detailed analytics on equipment performance and maintenance needs, customers can now proactively address issues, reducing downtime and operational expenses. This strategic move not only enhances customer satisfaction by improving equipment reliability but also opens avenues for ongoing revenue generation for the manufacturer.

Collaboration:

The project highlighted the critical role of collaborative innovation in achieving breakthroughs in industrial equipment management. HoloTrak’s dedication and technical expertise were instrumental in navigating the complexities of integrating CAN Bus data. The partnership was characterized by a mutual commitment to understanding the manufacturer’s unique needs, leading to the development of tailored solutions that enhanced operational efficiency and delivered exceptional value to customers.

This collaboration between HoloTrak and the industrial manufacturer not only set a new standard in equipment management but also demonstrated the transformative potential of advanced telematics solutions in driving the future of industrial operations. Through this partnership, the boundaries of what’s possible in equipment tracking and management were expanded, paving the way for further innovations in the industry.

Looking Ahead:

As HoloTrak and the manufacturer wrap up the initial phase of this innovative project, having met all predefined objectives, the groundwork for a potential market introduction has been solidly laid. This endeavor showcases HoloTrak’s expertise in spearheading telematics transformations, redefining standards for equipment management and operational efficiency across the industry. Moving forward, HoloTrak is poised to leverage this success, exploring further opportunities to innovate and provide cutting-edge solutions in telematics, reinforcing its position as a leader in technological advancements for equipment manufactures.